Which applications are possible?

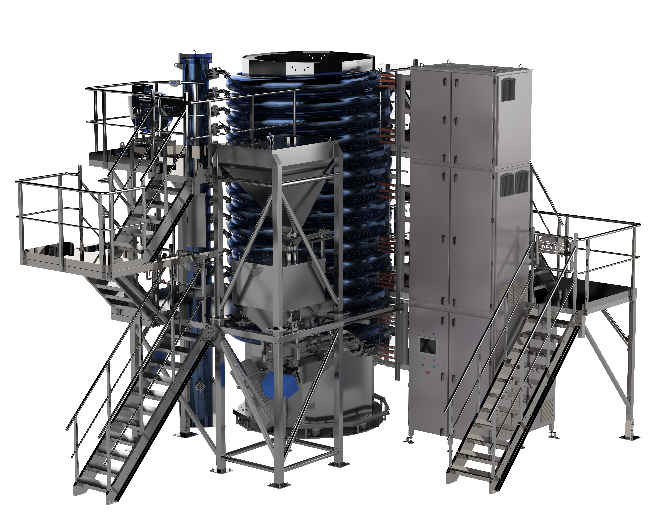

The industrial tailor-made heat treatment units designed by Revtech offer a continuous and perfectly plug flow. Flow rates start at 200 lbs/ and go up to 18,000 lbs/h.

Our unique and patented innovative solutions are supplied turnkey, they can be used for various applications simply by adapting the operating parameters of the equipment:

- Pasteurization / Steam sterilization: between 5 log and 7 log reduction of salmonella and pathogens. The technology is FDA certifiable and can be validated by an independent laboratory.

- Stabilization: enzymatic inhibition in order to increase the shelf life of the product.

- Kilning of oat groats prior to flaking

- Toasting / Roasting: wide range of product tastes and colours.

- Drying

- Heat treatment: modification of the functional properties of the flours.

- Puffing grains

For which agri-food products families?

- Nuts (pasteurization, roasting)

- Herbs & spices (steam sterilization, toasting)

- Seeds, oily seeds, ... (pasteurization, toasting/roasting)

- Cereals

Flours (pasteurization, stabilization, modification of functional properties, drying, toasting)

Barley and malt, ... (roasting)

Brans (pasteurization, stabilization, toasting)

Germs (stabilization, toasting)

Grains, ... (pasteurization, stabilization, toasting)

Oat groats (pasteurization, stabilization, toasting and kilning prior to flaking)

Wheat, buckwheat, rice, ... (puffing) - Flakes (stabilization, toasting)

- Pulses, soya beans, ... (pasteurization, stabilization - drying and enzymatic inhibition)

- Others:

Cocoa, coffee, ... (roasting)

Starches, ... (modification of functional properties)

This list is far from exhaustive. Contact us for more information.