Which applications are possible?

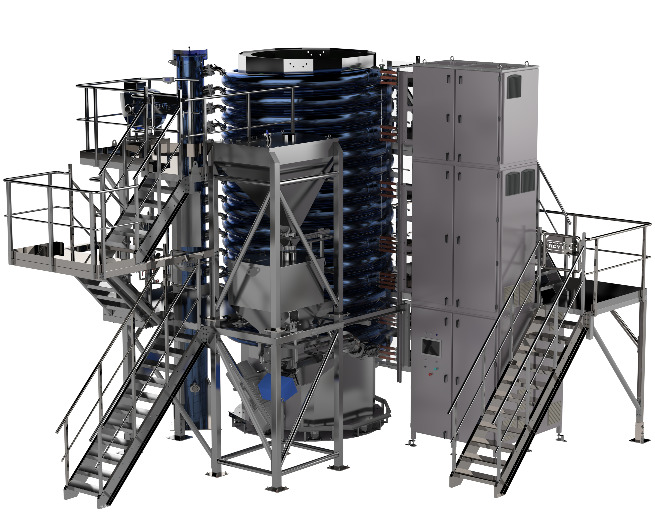

The industrial tailor-made heat treatment units designed by Revtech offer a continuous and perfectly plug flow. Flow rates start at 100 lbs/ and go up to 22,000 lbs/h.

Our unique and patented innovative solutions are supplied turnkey, they can be used for various applications simply by adapting the operating parameters of the equipment:

- Thermal desorption of synthetic rubber: VOC removal

- Drying adsorbent materials: reduction of water, alcohols…

- Polymerization of flame retardant

- Calcination of metal oxides

- Gas-solid reaction for catalyst activation

- Steam stripping for cork bark: TCA (2,4,6-Trichloroanisole) removal

- Pasteurization of cosmetic and pharmaceutical ingredients: 5 log kill up to 7 log kill step in compliance with the FDA

- Pyrolysis of agricultural waste

- Essential oils distillation of organic products

For which chemical products families?

Agrochemical:

- Synthetic Fertilizers, ... (drying)

- Mineral powders, ... (calcination)

Specialty Chemicals:

- Catalyst products, ... (gas-solid & solid-solid reaction)

- Desiccants, Adsorbent products (zeolites, MMCs), sorbents, salts, pigments, ... (drying)

- Mineral powders, Catalyst products, Metal oxides, ... (calcination)

- Metal oxides, ... (sintering)

- Solid compounds, ... (polymerization of powders)

- Synthetic rubber compounds, formaldehyde resin, ... (thermal desorption)

- Organic additives, fragrance oils, ... (torrefaction, distillation)

- Cosmetic & pharmaceutical ingredients (steam pasteurization)

- Food mineral additives, ... (pasteurization)

- Cork bark, ... (steam stripping)

This list is far from exhaustive. Contact us for more information.